Importance of a Chip Brush

By Andy Attaway

Bandsaws are an integral tool in many workshops, making efficient and precise cuts through various materials. But like any machinery, bandsaws have their vulnerabilities. One such vulnerability is chip accumulation, a problem that often goes unnoticed until it’s too late. But there’s a simple solution that many overlook – the chip brush.

Table of Contents

The Overlooked of Bandsaw Chip Brushes: Why Every Workshop Needs One

By Andy Attaway

What is a Bandsaw Chip Brush?

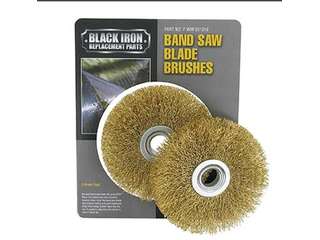

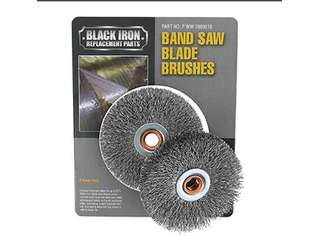

A bandsaw chip brush, often made with stainless steel wire, is a specially designed brush used to continuously remove chips from band saw blades. These brushes play a crucial role in extending the life and efficiency of your bandsaw blade.

Application & Features

Purpose: Chip brushes are primarily used to remove chips from band saw blades, ensuring a clean operation.

Universality: Whether you have a domestic model or an industrial-grade bandsaw, chip brushes are used on all band saw machines.

Specific Design: These brushes are made specifically for band saw applications. They aren’t your typical brushes; they’re designed to withstand the harsh environment of a working bandsaw.

Packaging: To ensure you’re always stocked, these brushes are shipped in a convenient 2 Pack, so you have a backup ready.

The Numerous Benefits

Longevity: One of the main advantages of using chip brushes is they will significantly extend the life of your band saw blade. When chips are not efficiently removed, they can wear down the blade, causing it to become blunt or even break.

Cost-Efficiency: With chip brushes ensuring the longevity of your bandsaw blade, you save money in the long run. No frequent replacements, no unexpected machine downtimes – just smooth operation.

Protecting the Machine: If left unchecked, chips can travel around the wheels of the band saw, destroying bearings and wheels. By getting rid of these chips early on, the chip brush safeguards your machine from potential damage.

The Common Oversight: The Importance of Proper Maintenance

While having a bandsaw chip brush is essential, its correct positioning and maintenance can’t be stressed enough. To avoid chip welding, your machine should ideally have a rotating wire brush that’s properly placed to clear away chips during cuts.

Setting the brush too far or too close from the teeth can lead to inefficiency and wear. The optimal position is for the brush to touch the deepest portions of the gullets without going beyond.

Not having a brush is a glaring problem. It’s surprising how many don’t realize their machine lacks this invaluable component. Not sure if you even have one? You should call your Metal Sawing Technology representative today.

Moreover, a poorly maintained or absent chip brush allows chips to ride along the blade. This can lead to severe damage, including getting caught in wheel bearings and carbide guides. Such neglect can result in premature malfunction of the equipment.

An alarming fact? Not replacing this inexpensive component can result in catastrophic damage to your bandsaw.

Five Tips to Get the Most Out of Your Bandsaw Chip Brush

Regularly Check the Position: Ensure the brush is touching, but not going beyond, the deepest portions of the blade’s gullets.

Clean the Brush: Over time, the brush can accumulate residue. Regular cleaning will ensure its efficiency.

Replace When Needed: Even the best chip brushes wear out. If you notice it’s not removing chips effectively, it’s time for a replacement.

Educate Your Team: If you’re running a workshop, make sure every team member understands the importance and maintenance of the chip brush.

Stock Up: Since they’re essential and affordable, it’s wise to order bandsaw chip brushes in advance to avoid any downtime.

Conclusion

The bandsaw chip brush, despite its modest size and cost, plays an essential role in ensuring the longevity and efficiency of your bandsaw. By investing in and properly maintaining this component, you not only protect your machine but also ensure cost savings in the long run.

Don’t let the small things lead to big problems. If you’re in need or unsure about the state of your bandsaw’s chip brush, contact Metal Sawing Technology today. Their expert team is always ready to assist you.

Wire Blade Chip Brushes for Bandsaws

Featured Video

Sign up for our Newsletter

Enter your email to receive sawing tips and latest product news.