Q501 I/C Structural Band Saw Blade: Precision, Strength, and Reliability

281-435-4411

The IC Band Saw blades feature a unique tooth profile that prevents over-feeding and the resulting stripped teeth.

Engineered for Structural Steel Cutting

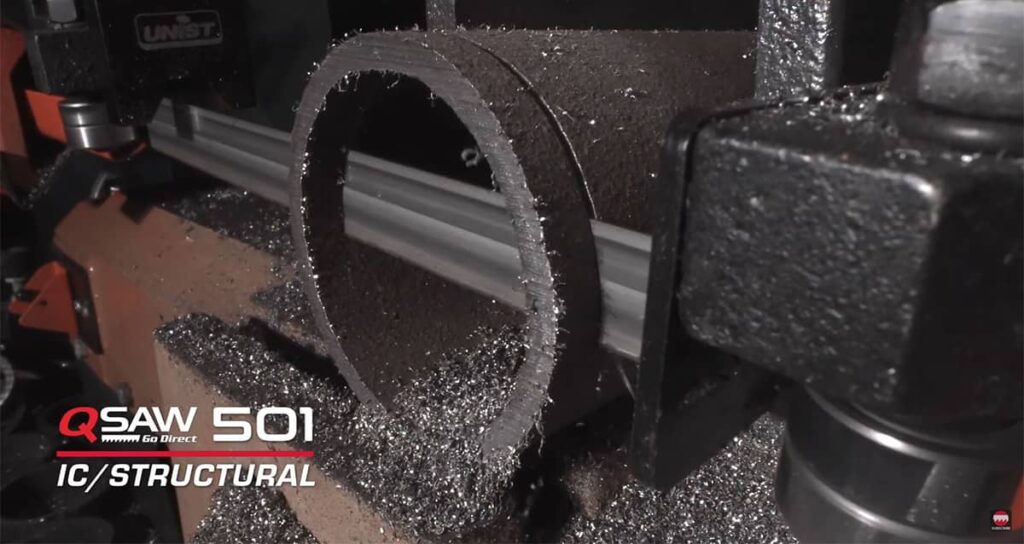

The Q501 I/C Structural Band Saw Blade is purpose-built for the demanding task of cutting structural steel. Whether you’re slicing through angle iron, channels, or I-beams, this blade delivers consistent performance, reduced vibration, and long-lasting durability. Designed for professionals in fabrication shops, welding environments, and heavy-duty steel applications, the Q501 I/C blade ensures clean, efficient cuts every time.

Key Features of the Q501 I/C Blade

The Q501 I/C Band Saw Blade stands out due to its thoughtful engineering and unique design elements, which cater specifically to structural steel cutting. Here are its standout features:

Specialized Tooth Design: Prevents overfeeding and eliminates stripped teeth, even when cutting sharp angles.

Heat-Treated for Durability: Proprietary processing enhances blade strength and eliminates the need for break-in cuts.

Reduced Vibration: The blade’s design minimizes noise and vibration, improving operator comfort and blade life.

M42 High-Speed Steel Teeth: The teeth, containing 8% cobalt, resist heat, abrasion, and shock for faster cutting.

Versatile Sizes: Available in widths from 3/4 inch to 2-5/8 inches, making it adaptable for a variety of structural applications.

Why Choose the Q501 I/C Structural Band Saw Blade?

Professionals choose the Q501 I/C for its ability to handle complex structural steel tasks with unmatched reliability. Here’s why this blade is a trusted tool in the industry:

Improved Blade Life: The triple-tempered M42 tooth material extends blade longevity by up to 20%.

Consistent Results: Special heat treatment ensures precise cuts while maintaining the blade’s integrity.

Noise Reduction: Minimized vibration reduces noise during operation, improving working conditions.

No Break-In Required: Start cutting immediately without preconditioning the blade.

Best Applications for the Q501 I/C Blade

The Q501 I/C Structural Band Saw Blade is versatile, tackling a variety of heavy-duty applications in industrial settings. It’s ideal for:

Cutting Bundled Solids and Tubes

Structural Steel, including channels and beams

Smaller Solids in fabrication and welding shops

Technical Specifications of the Q501 I/C Structural Blade

| Feature | Details |

|---|---|

| Material | M42 High-Speed Steel (8% cobalt) |

| Heat Treatment | Special triple tempering process |

| Sizes Available | 3/4″ to 2-5/8″ widths |

| Applications | Structural steel, tubes, solids |

| Tooth Profiles | 5/7, 8/11 for precision cuts |

Eliminating Break-In Cutting for Faster Results

One of the standout benefits of the Q501 I/C blade is its ability to perform at full capacity right out of the box. Thanks to a specialized treatment process, there’s no need for a break-in period. Operators can immediately achieve clean, accurate cuts without wasting time or energy. This innovation is particularly useful in high-production environments where efficiency matters most.

Tips for Optimizing Performance

To get the most out of your Q501 I/C Structural Band Saw Blade, follow these simple tips:

Use the Correct Tooth Pitch: For structural steel, select tooth profiles like 5/7 or 8/11 to ensure smooth cutting and reduced tooth stripping.

Maintain Proper Blade Tension: Adjust the tension according to your saw’s specifications to prevent blade drift.

Reduce Blade Vibration: Ensure the material is securely clamped to minimize movement and improve accuracy.

Regular Lubrication: Use appropriate coolant to keep the blade cool and prevent overheating during extended cuts.

Precision and Strength for Structural Steel Applications

When it comes to structural steel cutting, the Q501 I/C Band Saw Blade sets the standard for precision and strength. Its unique tooth configuration, triple-tempered M42 steel, and vibration-minimizing design make it the go-to blade for professionals handling I-beams, channels, and tubes. Whether in small fabrication shops or large industrial settings, this blade delivers results that save both time and money.

Explore More Blades for Your Cutting Needs

If you’re interested in learning more about why bi-metal blades are ideal for demanding tasks, don’t miss our article, “Why Bi-Metal Blades Combine Two Types of Steel.” Discover how bi-metal construction enhances performance, durability, and efficiency for cutting hard materials. Explore the details and elevate your sawing experience today!

Reliable Results with the Q501 I/C Structural Band Saw Blade

With its unmatched combination of durability, precision, and versatility, the Q501 I/C Structural Band Saw Blade is designed to meet the challenges of structural steel cutting. Its robust construction and advanced design ensure every cut is clean and accurate, making it the perfect choice for professionals seeking reliable performance.

Sign up for our Newsletter

Enter your email to receive sawing tips and latest product news.