Q701 M71 Hi-Production: The Ultimate Blade for Hard Steel Cutting

281-435-4411

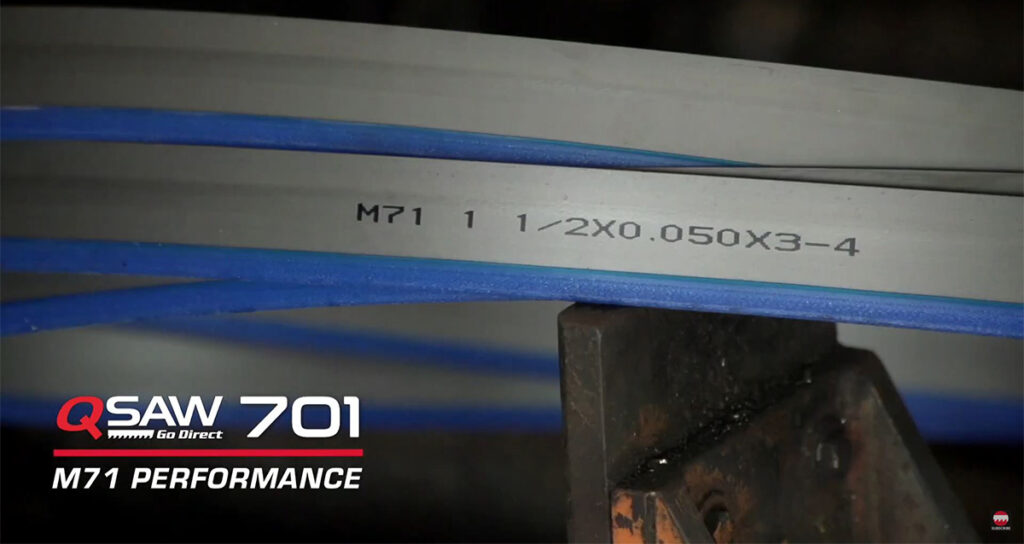

The 701 features a varying tooth height design with a M71 Tooth. The blade is made for cutting hard steels.

Q701 M71 Hi-Production: The Ultimate Blade for Hard Steel Cutting

When it comes to cutting hard steels and exotic alloys, the Q701 M71 Hi-Production Band Saw Blade stands out as the reliable choice for professionals. Designed for high-efficiency performance, this blade offers fast, clean cuts on even the toughest materials. Whether you’re working with Inconel, titanium, or hardened steels, the Q701 delivers unmatched precision and durability, making it a must-have for high-production applications.

Key Features of the Q701 M71 Blade

Here are the standout features that make the Q701 M71 Hi-Production Band Saw Blade ideal for cutting hard materials:

- Ground M71 Tooth Design: Ensures sharp, precise cuts and superior durability on tough alloys.

- Variable Tooth Height: Minimizes vibrations while allowing for aggressive, high-speed cutting.

- HRC70 Hardness: Provides the resilience needed to cut hardened steels and work-hardened materials.

- Enhanced Chip Ejection: The large gullet design improves chip removal, reducing heat buildup.

- Lower Cost Per Cut: Optimized performance reduces wear and tear, ensuring cost-effective cutting.

Ideal for Demanding Applications

The Q701 M71 Band Saw Blade is specifically designed for high-demand and high-production environments. It handles a variety of hard-to-cut materials with ease:

- Nickel-Based Alloys: Inconel, Monel, and Hastelloy.

- Work-Hardening Steels: Materials prone to hardening during the cutting process.

- Exotic Metals: Titanium and other high-tensile alloys.

- Large Solid Sections: Perfect for cutting solid bars and heavy-wall tubing.

No matter the challenge, the Q701 M71 delivers consistent performance and reduced downtime.

A Blade Built for Efficiency

The Q701 M71 is designed with advanced engineering to improve efficiency in cutting operations. Its variable tooth height design not only accelerates cutting but also reduces stress on the blade, leading to longer blade life. By combining aggressive cutting performance with precision, the Q701 is perfect for production shops aiming to maximize output without sacrificing quality.

Technical Specifications of the Q701 M71 Blade

| Feature | Details |

|---|---|

| Material | M71 Ground Tooth Bimetal |

| Hardness | HRC70 |

| Tooth Profile | Variable Height (VTH) |

| Applications | Hard steels, nickel alloys, titanium |

| Benefits | Fast cutting, low cost per cut |

The blade’s durability and engineering ensure that it meets the needs of both heavy-duty and precision cutting operations.

Why Choose the Q701 M71 for Your Shop?

The Q701 M71 Band Saw Blade is more than just a cutting tool—it’s a solution for reducing downtime and improving efficiency in demanding applications. Its ability to handle hard materials and deliver faster cuts sets it apart from other blades in its class. Professionals who rely on precision and durability turn to the Q701 for consistent, cost-effective results.

Simple Tips to Maximize Blade Performance

To get the most out of your Q701 M71 Hi-Production Blade, follow these practical tips:

- Choose the Right Feed and Speed: Adjust your saw settings based on the material being cut.

- Regular Maintenance: Keep your blade clean and inspect for wear to prolong its life.

- Use Proper Coolant: Lubricate during cutting to reduce heat and improve chip ejection.

- Ensure Tension and Alignment: Proper blade tension and alignment reduce stress and improve accuracy.

The Q701 M71 Hi-Production Band Saw Blade is the go-to solution for cutting hard steels and exotic alloys with speed, accuracy, and efficiency. Built with advanced M71 ground tooth technology and a variable tooth height design, this blade is designed to withstand tough applications while lowering your overall cost per cut. For high-production shops and industrial settings, the Q701 M71 delivers the durability and precision you need to stay ahead.

Sign up for our Newsletter

Enter your email to receive sawing tips and latest product news.